The Mrs actually asked me to brew a beer or something today because she felt the house was just ‘too dry’. Well, you don’t have to tell me twice- usually I get the side eye when I brew. However, my supply shop is closed on Sundays, and I didn’t have any hops, so I thought – why not get a whiskey mash going!? A while back, a local store decided to purge their grain supply, offering up to 90% off on unmilled specialty grains (seriously – wow). I spent about 100 bucks and got enough specialty grains to keep me going for a while! One of the items I procured was a 50 pound back of Crystal-60 malt. What if I make a whiskey made completely out of Crystal malt and maybe a little Debittered black Malt? Kind of like a porter grain bill? maybe something like a scotch? Well – I’m going to find out!

I filled a pot up with grain – 8 mugs of Crystal 60 and 1 mug of Debittered black – and started weighing everything up:

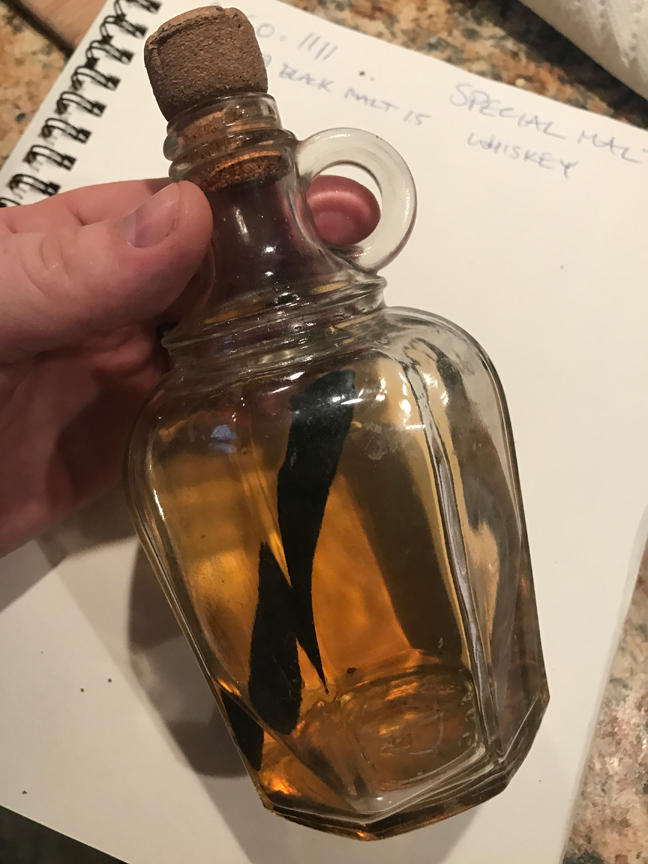

I always try to drink something I produced when I make beer or washes, and I decided to try the remaining Sweet Potato Whiskey that I made over a year ago – I threw a stick of oak in the bottle to let it keep aging while I sample it – it’s very smooth!

Let’s get these grains into the Mash setup!

Fire in the hole! (don’t judge the setup – judge the product)

In the meantime, I got my yeast going in a growler – I used a 1/4 cup of Red Star Distiller’s yeast and a half pound of brown sugar dissolved in water – Hopefully it does the trick!

Sparging:

This is what I ended up with:

Update: I just took a hydrometer reading, and I will admit, I’m kind of disappointed with it only being 1.045 I may have done something wrong – I’ll have to figure out why that may have happened – damn!

Worst case scenario is that my yield on the back end is low. Maybe I’ll let it boil for an hour before I finally cool it and pitch yeast…

Well,

Keep checking for updates!