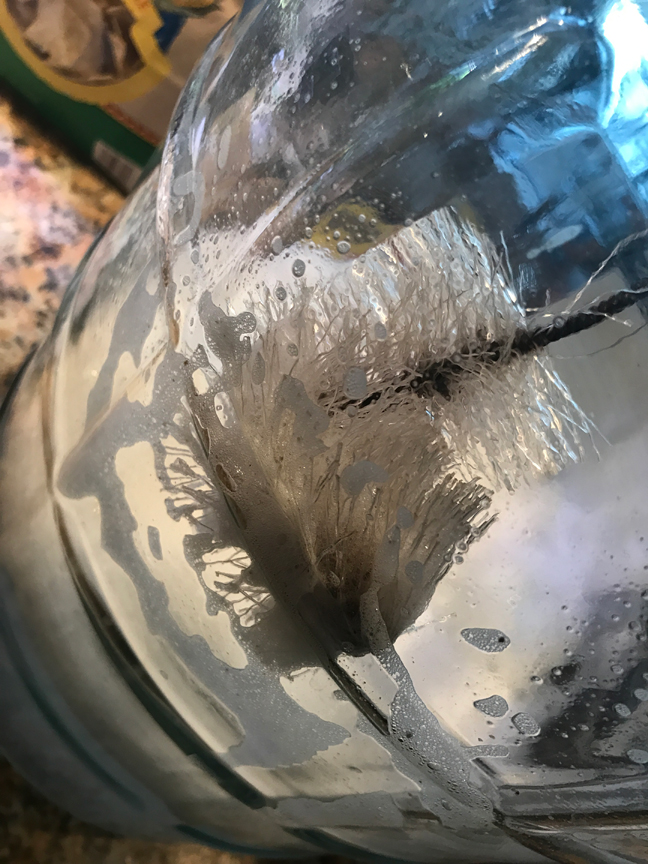

Behold – the carboy brush.

I don’t think there’s anyone that actually enjoys washing out a carboy or sanitizing equipment. For those that don’t know, the carboy (aka demijohn, aka 5 gallon or 6 gallon jug) is the big vessel that home alcohol crafting enthusiasts use to ferment their goods. The only thing that makes washing out a carboy any fun at all is the notion that it will be used to make alcohol in the near future. It’s a process, it’s ritual, and it’s kind of a pain.

At the store, they sell you a bunch of supplies to clean the carboy – one is the carboy brush, which is an absolute must. There is always a ring of dried up skinjaddi that forms where the surface of your fermentable was. A carboy brush is the only way to knock that out, aside from filling your carboy with solution all the way to the top and letting it sit for a month – which is inefficient when you’re trying to stay on top of your hobby. Usually the brush is only required to clean the top 1/4 of the carboy. If you don’t immediately clean the carboy out after emptying your alcohol and let the trub on the bottom dry out – you’re going to hate life. The problem is, it’s just a straight brush that looks like a smaller gauge toilet brush. To be effective, this brush needs to be molded correctly to do its job.

Behold my brush:

To the untrained eye, you’re looking at a bent, possibly ruined brush. But if you look at it closely, you’ll see it’s bent to reflect the shape of a carboy, and has a 90 degree bend in the middle of the brush portion. The bend is to allow for the actual brush portion of the brush to hit the outside of the glass rather than tip of the brush, which as you can see, doesn’t really have any bristles protruding out from it.

Inserting the brush into the carboy isn’t as easy as if it’s a straight brush, but it’s not as hard as you would think, and it makes pulling the brush out better, because you kind of rotate it out rather than popping it out – which if you’ve ever done with a wet carboy brush, you get sprayed in the face unless you block the spattering with your hands.

Next, you want to make sure you loop a finger into the loop at the end of the brush so that you don’t accidentally drop it into your carboy.. Not that it’s a huge pain in the ass to get out – but if the carboy is full of sanitizer it can be. From there, it’s an easy open and closing of the hand to make the brush swish back and forth on the inside of the glass for optimum agitation.

You can see the fine line of dried skinjaddi on the bottom right image above that I’m trying to knock off – it’s gotta happen! A quick lowering into the sanitizing solution at the bottom of the carboy, and I’m whippin up some good suds! It’s not hard at all.

Now that I have a clean carboy, it’s time to rack my Fresh Slice clone onto some hops! I switched up the recipe at the last minute after getting the 4oz of wet hops from Neal’s the other day – can’t let those go to waste!

Yes, they might be a pain in the ass to get out, but I don’t care – think of all the FLAVOR!

Some of you might be asking ‘but you just picked these off a bine – aren’t you nervous about the sanitation of the hops? what if there’s ant larvae or spiders in there? Well sure I’m worried about that, but I’m not really. I rinsed off the hops as well as I could, gave them a good inspection for insects.. I’m not too worried about bacterial growth because the beer it is going into is about 6.5% abv, so there’s enough alcohol to kill off the normal infections. Plus, even if it gets weird, I know I can age the beer and it will eventually taste awesome. This is what home brewing is all about!

I got everything taken care of, and celebrated with a little scotch. Happy Labor Day weekend!