Last Friday was national beer day – sorry if you weren’t informed – chances are if you screw around on Facebook and have alcoholics for friends like me, you knew, and celebrated accordingly. We’re in saving mode currently, and didn’t really want to go out and celebrate too hard, so the plan was to go get something to eat with a couple beers, then go grab some beer to drink back at the house.

Some of you may recall my bizarre experience at the Buffalo Taproom & Grill – where I went by myself for a bite to eat and ended up a 3rd person observer to intense conversation where it started to feel like I was the person who had died. Well, I decided to make a new memory there and get a couple pints of beer and some wings.

And by ‘couple’, I mean ‘3’ – and they were all the CB’s Double IPA – which was really hitting the spot with the Suicidal Wings that I got – Perfect amount of spice and flavor – definitely made up for the ‘ok’ Tacos I had there during my last visit.

No I did not eat them all. But they look F’ing great, right?

Also had some Onion Petals – delicious of course…

From there, we went to Noco and I decided that to keep my budget down, I would drink Bud Light. Yes, even a craft brew / homebrewer like myself likes a nice, crisp, easy to drink, cold macro beer from time to time. It’s refreshing and nostalgic! These heavy beers weren’t around when I started drinking, and in College – you drink the cheaper stuff! Heck, I think Yeungling and Honey Brown were as ‘craft’ as it got when I was in College..

So yes, I was in the mood for Bud Light. Also, I realized I needed to free up a Carboy for racking my Hefeweizen in the near future. The only carboy I could free up was the one that had a Whiskey wash ready to go in it. So – I managed to convince my buddy with the still (licensed) to come over and set his gear up to run a batch.

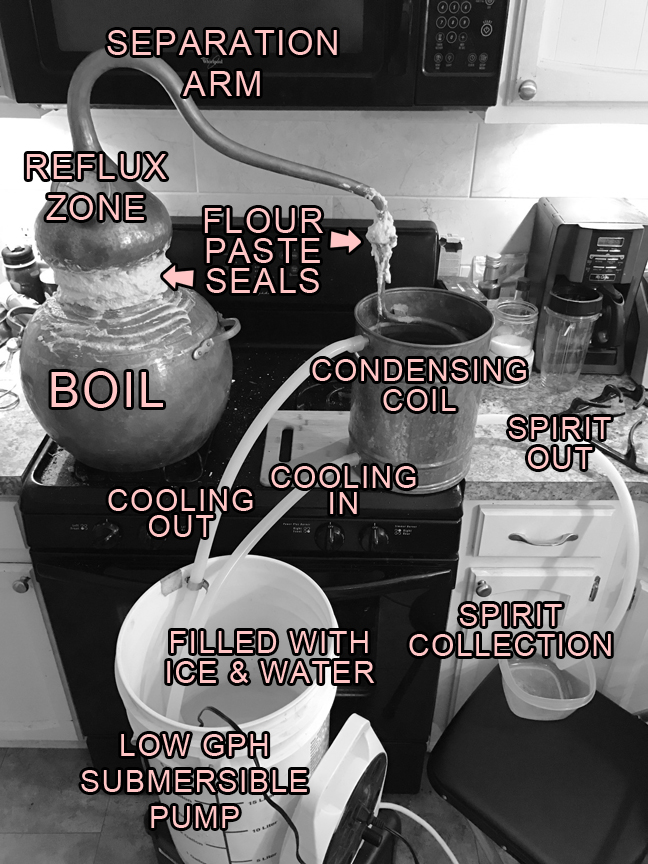

So, this is probably the first time I’ve shown this thing in action – so for those of you that have NO IDEA what you’re looking at, here’s the same picture with some labels to help you understand what you’re looking at!

Now, here’s a quick breakdown of how this hand-made copper still works: You basically brew a high abv beer, but without the hops, add extra sugar, then use a distillers’ yeast (or any yeast for that matter) to ferment it in a carboy. When it’s done fermenting, you rack it into the boil kettle, then attach the reflux onion/separation arm, which then attaches to the condensing coil. Flour paste is used to seal up all the connections so there are no leaks, otherwise this could get dangerous!

When the beer (wash) reaches 173 degrees, the alcohol in it begins to boil. Water doesn’t boil until 212 degrees, but it is however starting to evaporate at this point. So the result is, that alcohol saturated clouds begin rising up into the reflux area – some of the clouds condense on the walls of the reflux zone, and dribble back down into the kettle. The reflux zone basically does its best to knock as much water as it can back down into the kettle, and only allow alcohol to get up into the separation arm. At first, only the strongest alcohol makes its way up into the separation arm, where it’s drawn towards the condensing coil, which is being chilled by circulating ice water. Once it touches the cold copper of the condensing coil, it turns from a vapor back into a liquid – with this still, it’s about 75% abv when it first comes out. The first 50ml of the 5 gallons is actually not the type of alcohol that you want to drink – it’s more of a lighter fluid than digestible alcohol, and needs to be thrown out. After 50ml is collected, we start making our cuts.

(50ml of nasties in the tupperware, followed by heads and hearts)

Cuts are made to split the batch up into various stages – they are referred to as Heads, Hearts and Tails. Logic would let you know that the Heads are the first runnings to come out of the still after the nasties, Hearts are the middle of the run, and the Tails are at the end and very weak. I like to collect them in a long line of glasses:

The goal is to never let the still run too hot, you want a steady drip of about 1 drip a second – if you run too hot your booze will end up cloudy. This actually happened on this run. In the picture below, you can see that the 4th receptacle in from the left has a little cloudiness to it – that cloudiness transferred to the whole batch after I made my blend – it doesn’t make the liquor taste bad, but you want crystal clear whiskey that you can be proud of – not slightly cloudy – that ain’t right. The only way to fix it is to re-run your spirit. I just might, but add the whole batch to a new run – that would be the best thing to do anyways – I’d end up with some serious product if I did that!

This first cut of heads was crystal clear –

Check the church windows on that glass – that’s a sure sign that you’ve got some spirits in that thar glass!

So at the end of the run, you’ve got all of the booze laying in front of you – and you get to play ‘master blender’ where you slowly add your alcohol together to make something that you like. My rule of thumb is to take very small sips of each cut, starting at the last tail cut, and work your way up the line until you find the best cut. If your cuts are as frequent as mine, this is easy to find and you can sip and find what you would consider the ‘mamma bear’ cut – not too harsh, but not dull – flavorful and chock full of aroma. I put a half shot glass of that on the side and keep it as my control sample. Then I will take the rest of the best cut and put it in a large vessel. From there, I add the cut that’s closer to the head, then add tail cuts until it matches my control. Then I add the next cut closest to the head and repeat the process. I work my way up until I have the first head cut left, which I only add half of (because there could still be a little of the nasties in that one. I put the other half of the first head cut and the rest of the tails in a container to wait for the next run.

The resulting blend get’s tested one last time:

Once you feel great about it – it goes into a clear growler with some charred oak – then into the basement to be forgotten about for a minimum of 1 year (with the date labeled on it). I don’t really get enough spirit from a 5 gallon batch to require a full-on barrel, but I guess I could turn up production and get one going. The sticks honestly work just fine for the small batch sizes I do.

Big up to my buddy (anonymous) who let me piggy back on his license to make this product – We kicked the keg of my Dark Red Ale that night after I ran out of Bud Light, and he got paid in BBQ for his time. I’m tempted to rerun this batch and get rid of the cloudiness, but we’ll see…

Cheers everyone!